Future Energy Solutions

We excel in delivering cutting-edge solutions for the automation of EV battery manufacturing. Our expertise spans various aspects, including:

1. Battery to Module Assembly Automation

2. Module to Pack Assembly Automation

3. Cell Manufacturing Automation

4. Comprehensive Busbar Manufacturing Line Solutions

With a commitment to innovation and precision, we empower the future of electric vehicle technology through our automation solutions.

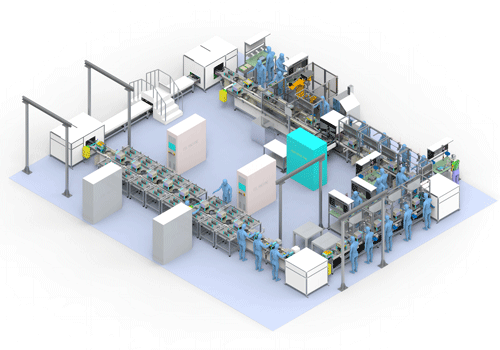

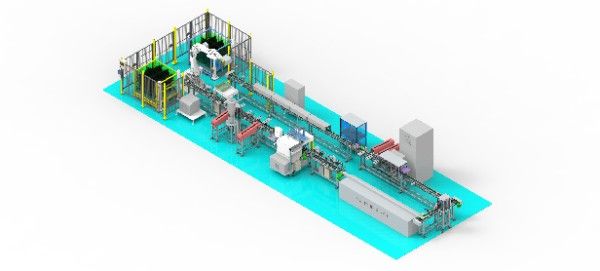

Cell to Module Assembly Line

Cylindrical Assembly Line

- Automation: Semi and fully automated lines.

- Capacity: Equipment handles ≥ 40 parts per minute (PPM).

- Quality: Individual machine pass rate of ≥ 99%.

- Compatibility: Supports a variety of high-end EV products.

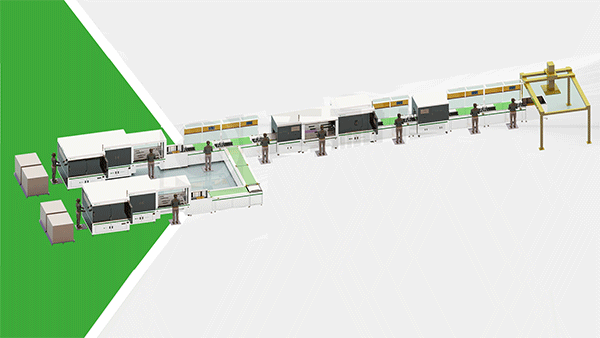

Cell to Module Assembly Line

Prismatic Assembly Line

- Efficiency: 12 parts per minute (ppm) with high automation and minimal manual effort.

- Compatibility: Supports a wide range of high-end EV products.

- Quality: Equipment pass rate of ≥ 99.9%.

- Flexibility: Semi and fully automated lines available.

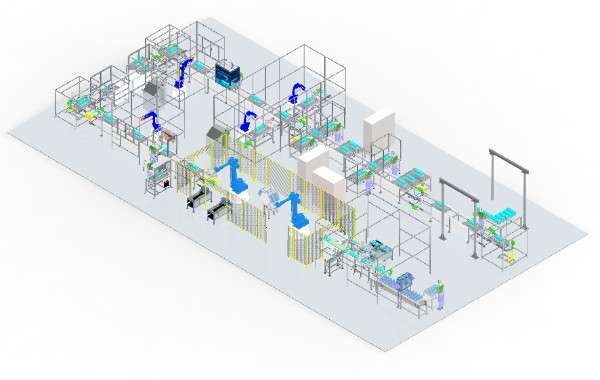

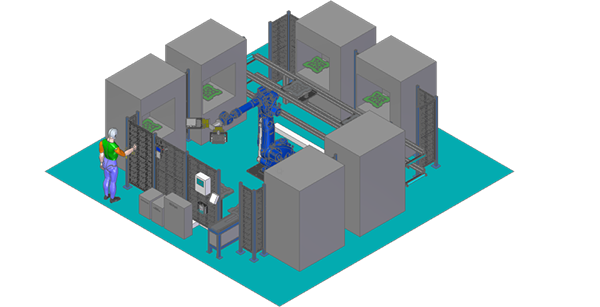

Module to Pack Assembly Line

Cylindrical Assembly Line

- Automation: Semi and fully automated lines.

- Capacity: Equipment handles ≥ 40 parts per minute (PPM).

- Quality: Individual machine pass rate of ≥ 99%.

- Compatibility: Supports a variety of high-end EV products.

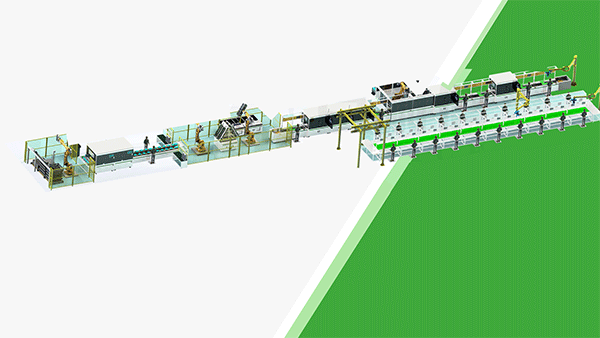

Module to Pack Assembly Line

Prismatic Assembly Line

- Efficiency: 12 parts per minute (ppm) with high automation and minimal manual effort.

- Compatibility: Supports a wide range of high-end EV products.

- Quality: Equipment pass rate of ≥ 99.9%.

- Flexibility: Semi and fully automated lines available.

Battery Solutions

Lead Acid Battery Testing Line

Our Lead Acid Battery Testing Line delivers a complete solution for comprehensive testing and quality assurance of lead-acid batteries. This state-of-the-art system is equipped with advanced diagnostic tools and automated testing equipment, designed to provide precise analysis and accurate performance evaluation.

Battery Solutions

Lead Acid Battery Pack Burning Cell

Lead acid battery packs can experience cell burning due to overcharging, internal short circuits, or sulfation. This can release toxic gases and pose fire hazards. To prevent this, regular maintenance, proper charging practices, and using battery

management systems (BMS) are essential. These measures help monitor cell health and ensure the safety and longevity of the battery pack.

Battery Solutions

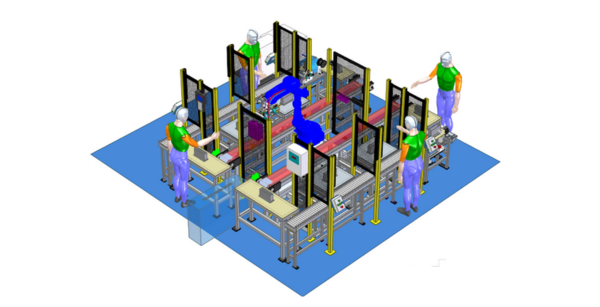

Machine Tending for Spot Welding of EV Cells

Machine tending for spot welding of EV cells automates the precise handling and welding of battery cells, ensuring quality and efficiency. Advanced robotics position and weld each cell accurately, reducing human error and increasing production speed. Integrating vision systems allows robots to correct misalignments in real- time, enhancing reliability. This automation streamlines manufacturing and supports scalability, meeting the demand for electric vehicles with dependable battery solutions.